It is simple to operate, which can save a lot of labor.

It is fast in mending, which can reduce production costs.

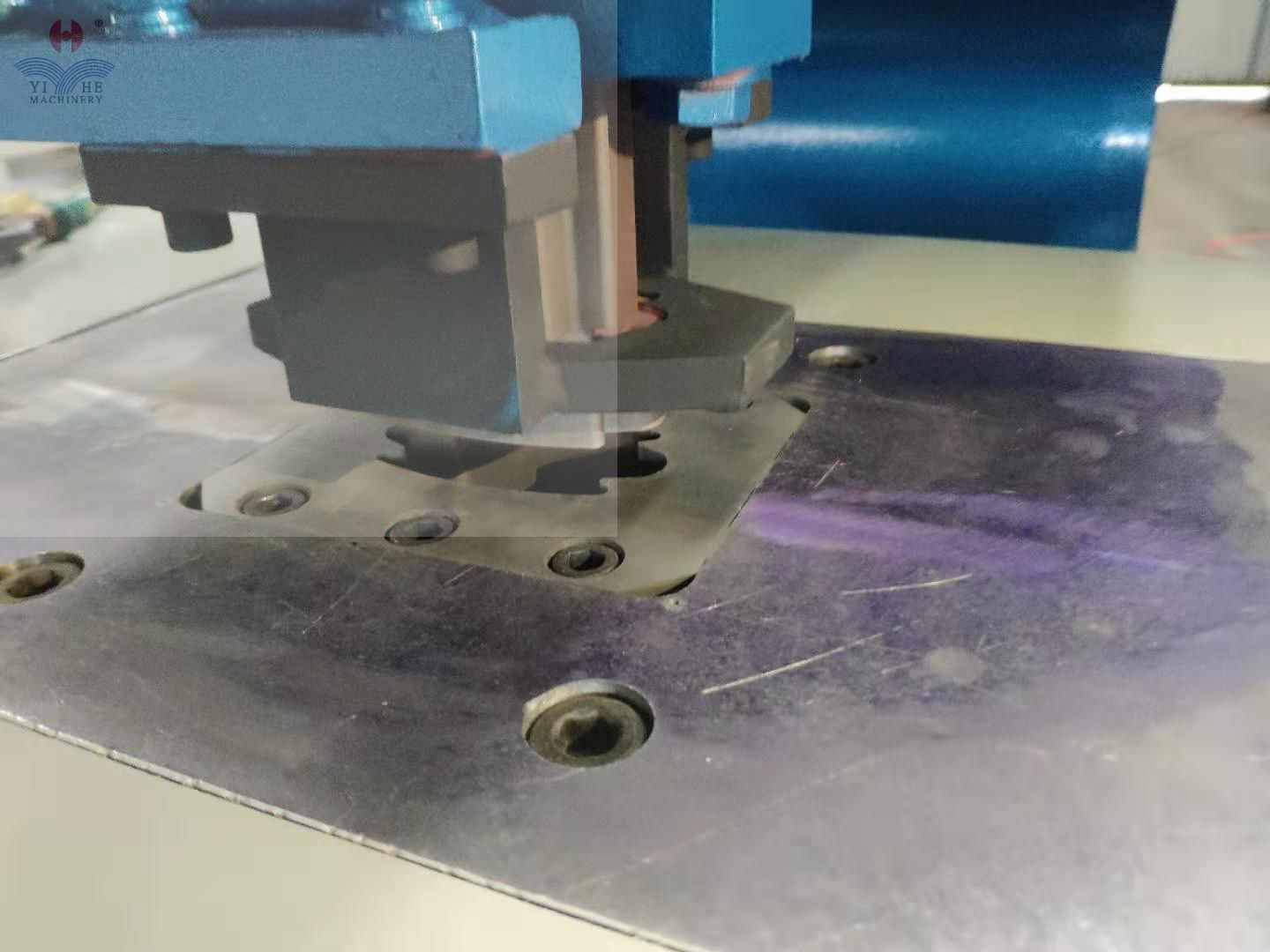

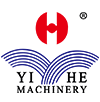

Patching veneer thickness: | 0.8-3mm |

Patching veneer size: | 60*100mm |

Working speed: | About 3-5s/time |

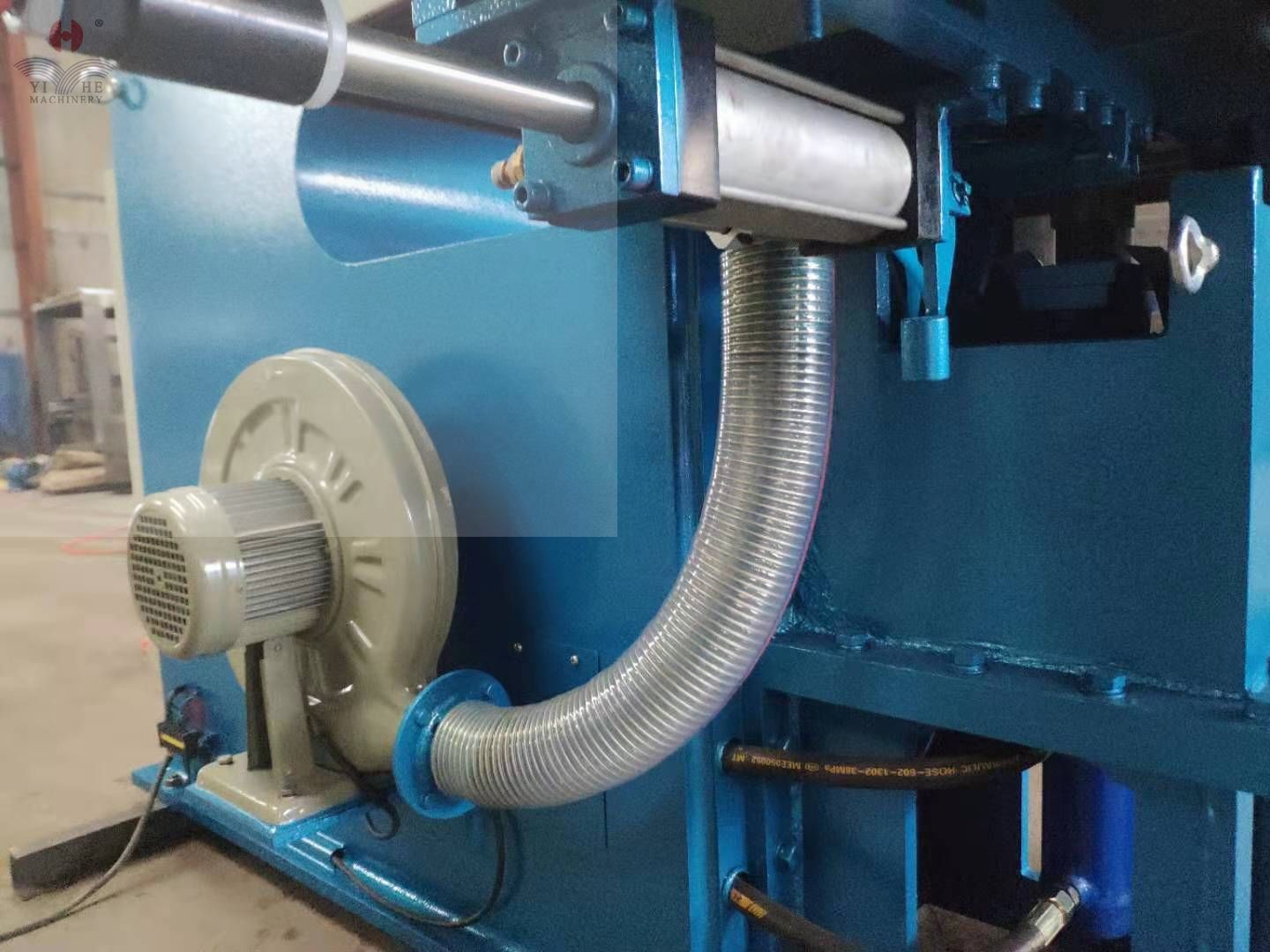

Power: | 4.25KW |

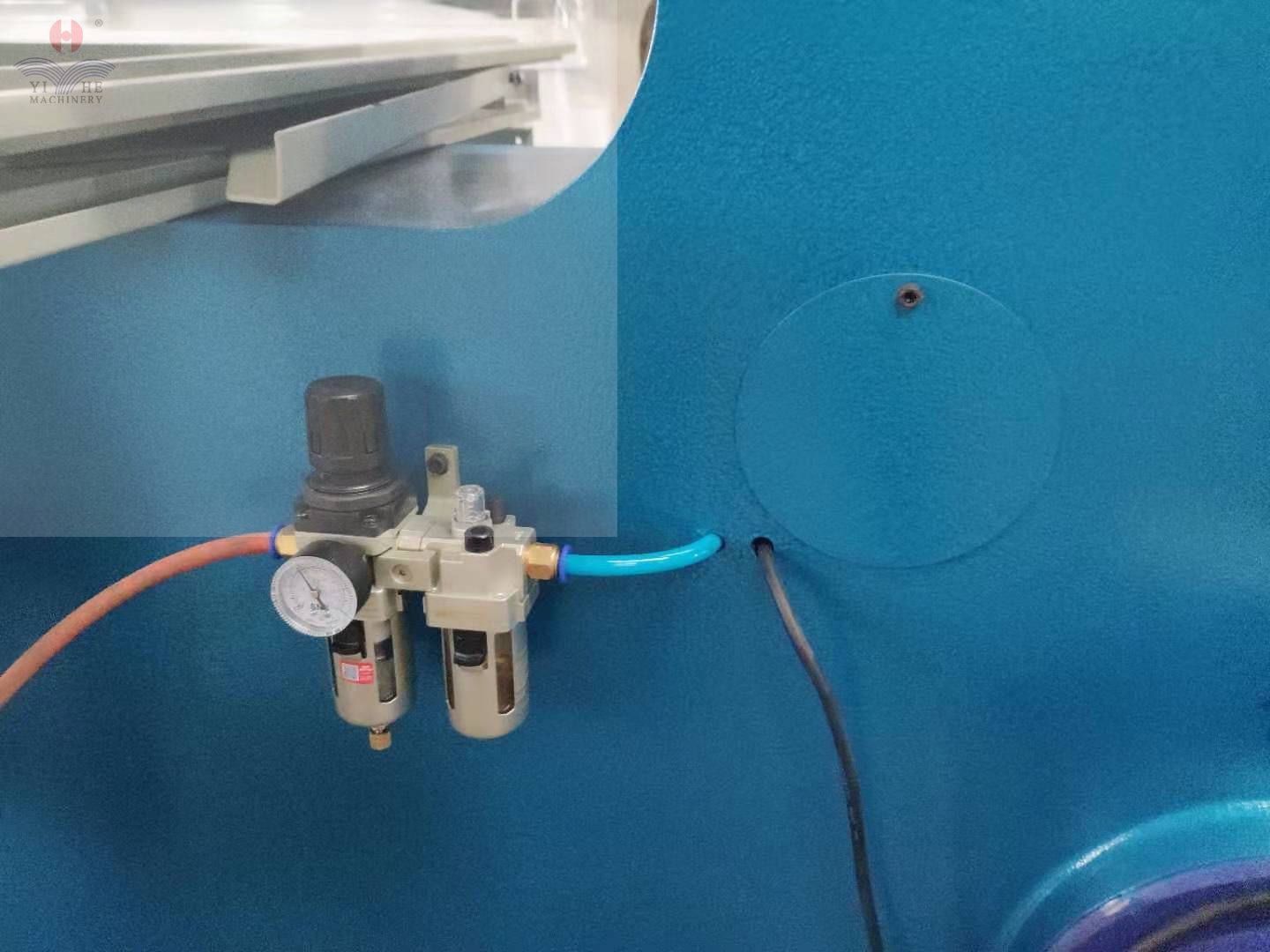

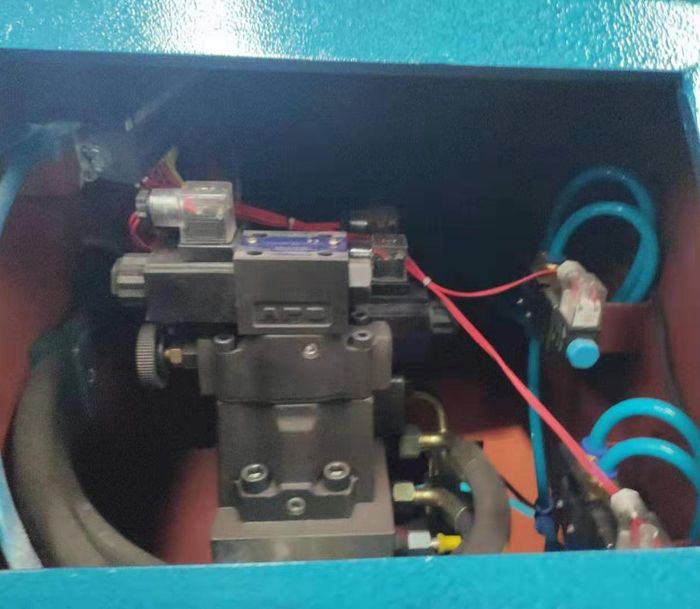

Compressed air: | 4-6kg/cm2 |

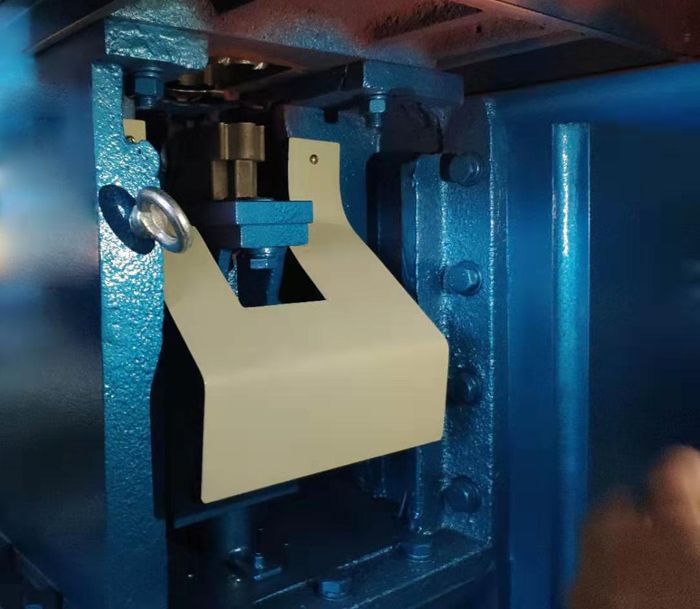

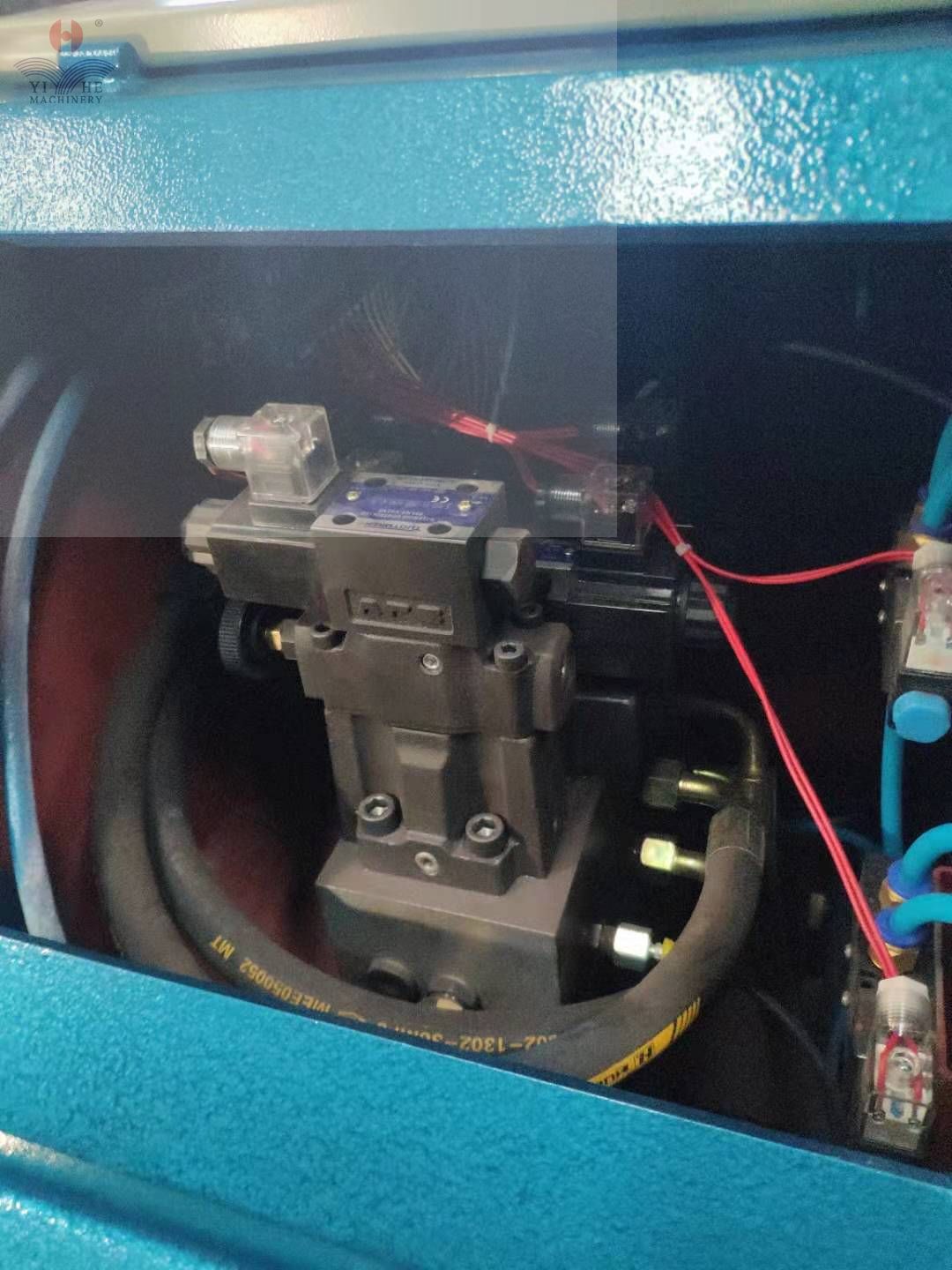

Rated oil pressure: | 16MPa |

Cylinder diameter: | Ø63mm |

Overall size: | 1650*1300*1750mm |

Machine's weight: | About 1300KGS |