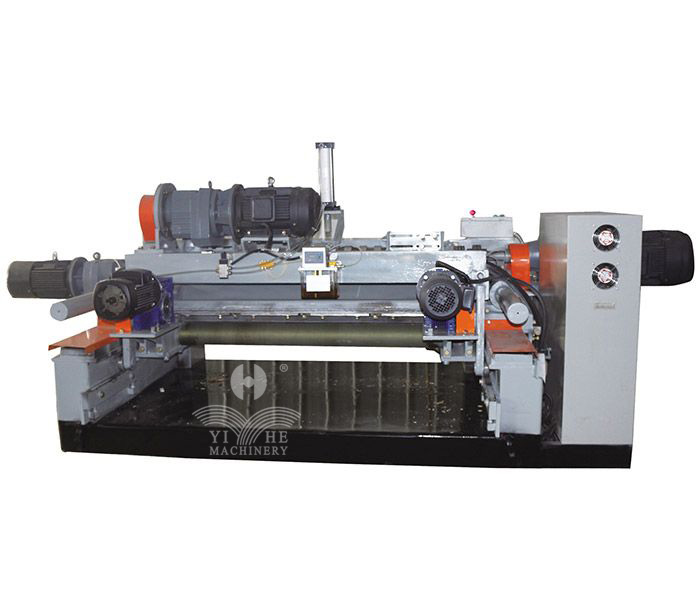

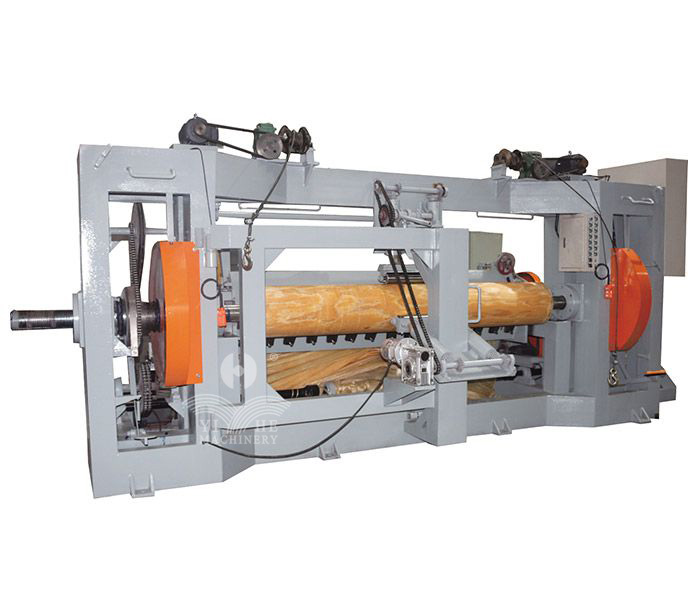

1. Euipped with automatic lubrication system, ensure machine running stable, so the using life of the machine is extended.

2. Feeding system is designed into leading screw and screw nut which is made from alloy.

This design guarantee feeding system synchronizing go forward and backward, so the veneer is in same thickness and smooth surface.

3. The linear speed of host machine is fixed and can’t be adjustable.

4. Min. diameter of the wood core after peeling is 30mm, can max. help our client save wood log material.

5. Equipped with double pushing air cylinder in the upper squeezing rollers, can drop the left wood core with quick speed.

Model No.: | YPM/8DCNC |

Wood length: | 2000-2600mm |

Wood diameter: | Φ30-Φ450mm |

Blade length: | 2700mm |

Thickness of veneer peeler: | 0.5-4.0mm |

Linear speed of host machine: | 30m/min |

Double roller diameter: | 118mm |

Double roller motor power: | 7.5kw*2pcs |

Single roller motor power: | 7.5kw*2pcs |

Feeding motor power: | 7.5kw(servo motor) |

Total power: | 37.5kw |

Total weight: | 6000kg |

Machine dimension: | 5500*1800*1400mm |